|

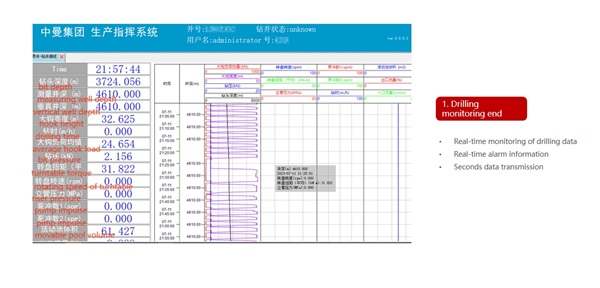

Production command system

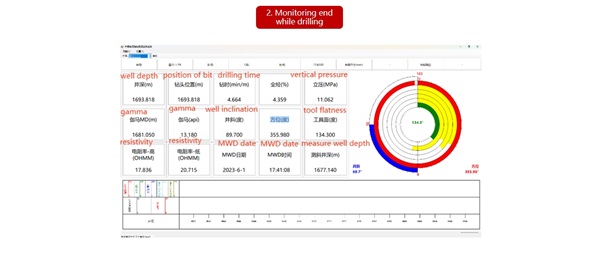

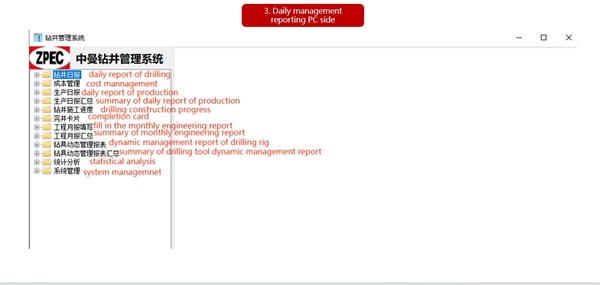

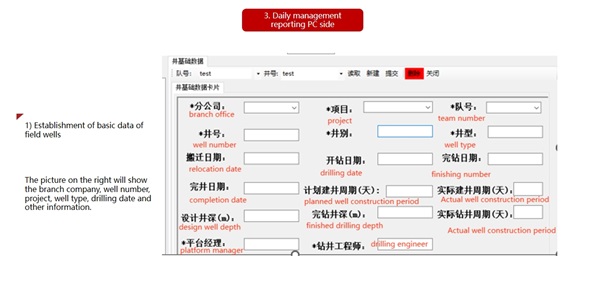

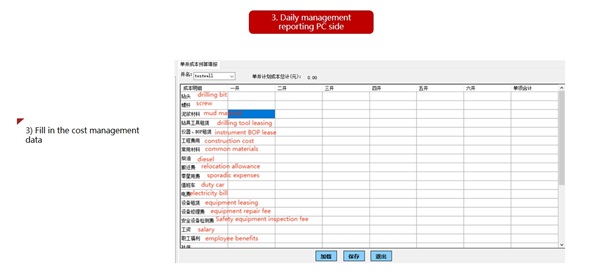

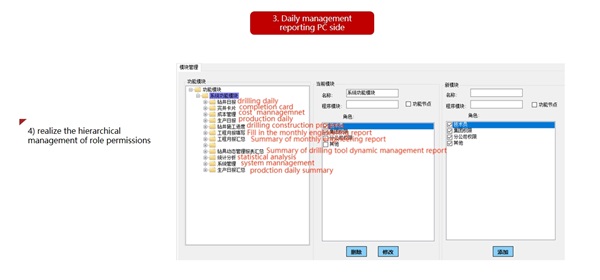

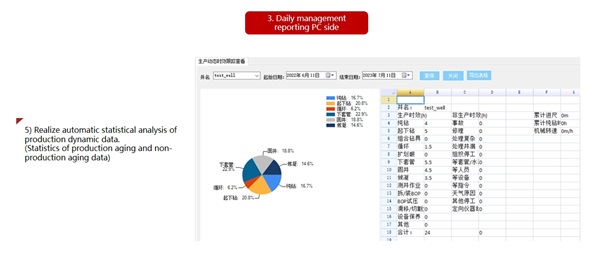

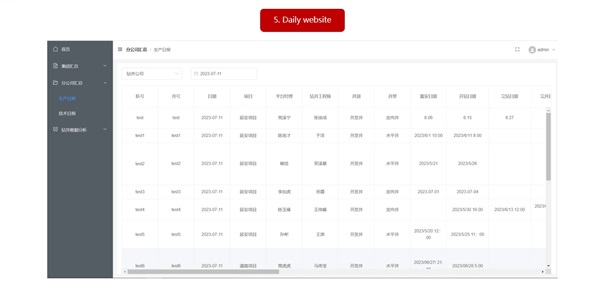

The production command system can carry out drilling monitoring, monitoring while drilling, daily report management and other operations, and realize real-time monitoring of drilling data, real-time alarm information, second-level data transmission, establishment of basic data of field wells, reporting, summarizing and viewing of drilling daily report, production daily report, technical daily report, monthly report, drilling tool management report, cost management data reporting, hierarchical management of role authority, automatic statistical analysis of production dynamic data, and automatic statistical analysis of production dynamic data (production timeliness and non-production timeliness data statistics). Its necessity lies in:

1. Managers at three different levels-Group Headquarters-Project Base-Field Drilling Team can check the production and operation status of drilling team in real time through the Internet without geographical restrictions;

2. The on-site drilling crew fills in the daily report, which greatly improves the efficiency compared with the previous reporting method;

3. It has the functions of real-time remote transmission of operation parameters, real-time entry of engineering reports, production efficiency and dynamic analysis of engineering progress, and becomes a network bridge connecting the construction site and the drilling management department;

4. Innovate and upgrade the digital and intelligent remote transmission system, find abnormal working conditions in advance, and solve existing problems through collaborative analysis, thus eliminating many hidden dangers of underground accidents, ensuring safe production and improving the working efficiency;

5. Through this system, video and data can be transmitted in real time in some special wells and key wells of drilling projects at home and abroad. Since the system has been in operation, the transmission is stable and the data is real and smooth, which provides sufficient basis for synchronous analysis, rapid diagnosis and scheme formulation by front and back expert teams, and improves the effectiveness of remote guidance for solving various problems on site;

6. The computer stores data locally to ensure data integrity in case of network interruption;

7. Remote maintenance, which means that the edge terminal can be maintained without going to the site, and the logic operation rules can be issued, the program can be upgraded, and remote diagnosis can be realized through the server. Remote management and maintenance reduces the presence of personnel for maintenance and reduces risks;

8. Permanently save massive historical data to help production process and accident analysis.

The production command system has the following characteristics:

1. Independent research and development, focusing on the innovative products of "convergence, integration and application" of big data in the oil industry.

2. The data transmission is stable, true and smooth.

3. Early warning of abnormal working conditions in advance

4. China-Malaysia independent intellectual property rights

|