|

Top Drive Slide Drilling Control System

Introduction and Evaluation of Drilling Crew

First, the significance of drilling crew use:

At present, during the horizontal drilling and directional drilling stage, the problem of drilling tool holding pressure is common at home and abroad. The specific performance is that the WOB cannot be applied to the bit, and the WOB has been applied sufficiently. However, the drilling is slow and easy to get stuck, so it is necessary to lift the drilling tool back and forth. At the same time, it is also difficult to orient due to sticking, which leads to long horizontal drilling time and slow progress. In view of this situation, we have designed and developed a control system for top drive drilling tools, which is suitable for all kinds of top drives of Zhongman, and can also be suitable for other brands of top drives at home and abroad if the conditions are met.

Second, the cases used by the drilling crew:

On June 25th, 2023, slide drilling control system was verified in the No.2 Drilling Team of Zhongman, Yan 'an. The team used 500-ton top drive of Jinghong for operation, and started to use the slide drilling control system after being connected with the wiring of the top drive electronic control system in a horizontal operation section of more than 3,000 meters. The following figure shows the layout of the slide drilling control box after installation.

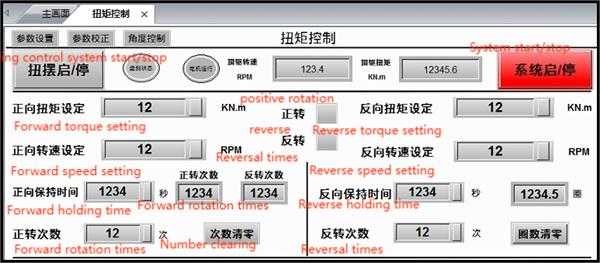

slide drilling control system first inputs various necessary parameters, such as drilling tool make-up torque, rated torque, gear box transmission ratio, etc., and sets the speed and torque control limit values. After switching to the slide drilling control system , the operation control of the top drive motor is taken over by the slide drilling control system . After the initial setting and calibration are completed, return to the torque control interface, set the forward and reverse torque and speed, and carry out the trial operation of slide drilling control.

For safety, the maximum forward torque limit is 14KN.M, and the maximum reverse torque limit is 12kn.m.. The maximum speed is set to 30RPM in both forward and reverse directions. The following figure shows the interface for setting parameters in torque control mode.

The positioning function of the slide drilling has also been tested. The encoder signal of the spindle of the top drive motor is divided into two by the encoder signal distribution module, and then the position signal is provided to the slide drilling control system , without affecting the closed-loop control of the top drive motor. The operation interface should be as simple and convenient as possible. When the spindle needs to rotate forward or backward for a certain angle, press the positioning enable button, input the angle to be deflected, select forward or reverse rotation, and press the positioning start/stop key, and the spindle will automatically rotate to the specified angle and then stop. Under the condition of hanging drilling tools, the positioning accuracy is basically within 1. When the spindle is idling without load, because the inertia deviation exceeds 1, it can be corrected by setting the correction coefficient to control the control accuracy at about 1.

On-site demonstration of the positioning function of spindle reverse rotation of 20 degrees, select reverse after setting the angle, click positioning to start spindle automatic reverse rotation of 20 degrees and then stop, and the real-time angle display angle is 20.92 degrees. The positioning operation is normal.

III. Comparison of Torsion Pendulum Control System before and after use:

Before use: the driller can only carry out directional operation at the WOB of 18-20 tons, which is easy to jam, and it is necessary to lift the drilling tool from time to time before operation, and it also takes a lot of time to locate the tool surface.

|

drilling crew |

Drilling depth (m) |

Pump pressure (MPa) |

WOB (ton) |

|

SCP50056 |

3368 |

18-19 |

18-20 |

After use: set drilling parameters and use effect after the drilling tool torsion pendulum system is put into use;

|

drilling crew |

Drilling depth |

pumping pressure |

bit pressure |

Forward torque |

Reverse torque |

Forward speed |

Reverse speed |

|

SCP50056 |

3410m |

17-18Mpa |

25 tons |

14KN.m |

12KN.m |

15r/m |

15r/m |

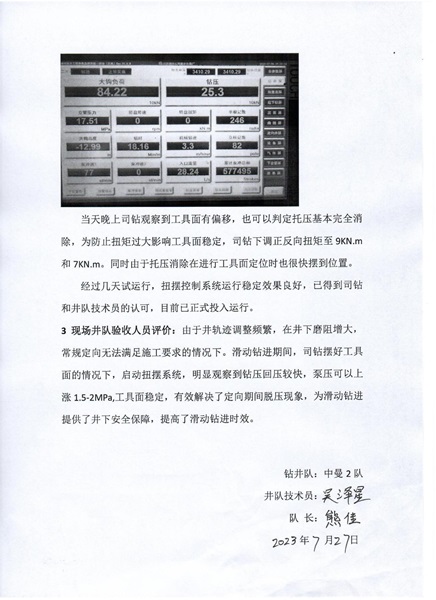

Description: After slide drilling control system was put into use, the driller increased the WOB to 25 tons, and the slide drilling process was stable, and the forward and reverse rotation balance was smooth. It takes about 32 seconds to keep still after rotating forward to the maximum torque, and it takes about 7.5 turns. Reverse rotation until the maximum torque remains static for about 30 seconds, and rotate for about 7 times. It is obviously observed that the back pressure of WOB is relatively fast. When the driller sets the tool surface, the pump pressure of starting the slide drilling control system can be reduced by 1.5-2MPa, and the tool surface is stable, which effectively solves the phenomenon of pressure loss during orientation, provides downhole safety for sliding drilling, and improves the efficiency of sliding drilling. The following figure shows the actual data of WOB, well depth and pump pressure.

After several days' operation, slide drilling control system has a good stable effect and has been recognized by the driller and drilling crew technicians.

Iv. evaluation of drilling crew:

|